Determining the Pouring Surface and Techniques for Precision Casting

The position of a casting within the mold during the pouring process affects the quality, dimensional accuracy, and molding complexity of precision castings. The principles for selecting the pouring position are as follows:

Precision Casting Pouring

1. Important or Main Machined Surfaces Facing Down or to the Side:

· During pouring, gases, slag, and sand particles in the mold tend to float upwards, which may cause defects like porosity, slag inclusions, and sand holes in the upper part of the casting. Conversely, the lower part of the casting is less likely to have such defects and tends to have a denser structure.

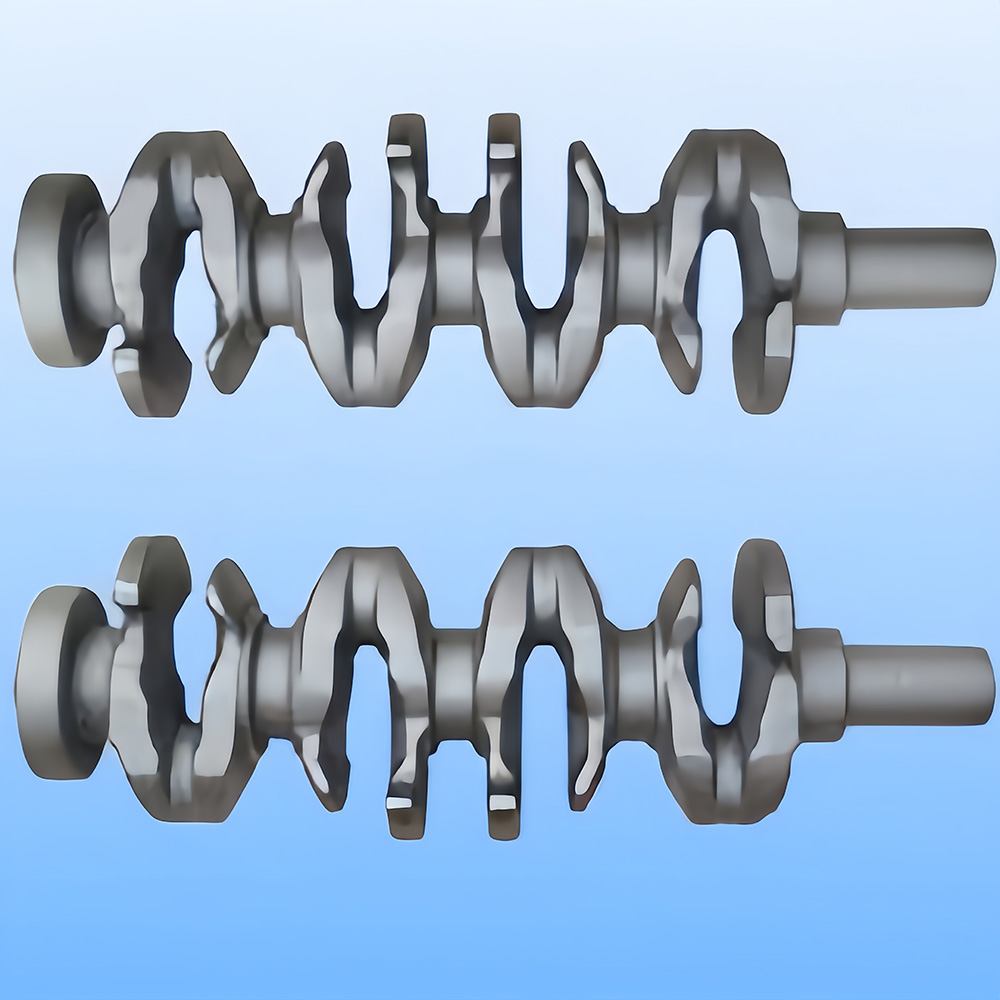

· For instance, when casting a machine tool bed, the guide rail surface should face downwards to ensure the quality of this critical working surface. If the cylindrical surface requires high quality, a vertical pouring scheme can be used to place the cylindrical surface to the side, ensuring uniform quality.

2. Large Flat Surfaces Facing Down or Tilted During Pouring:

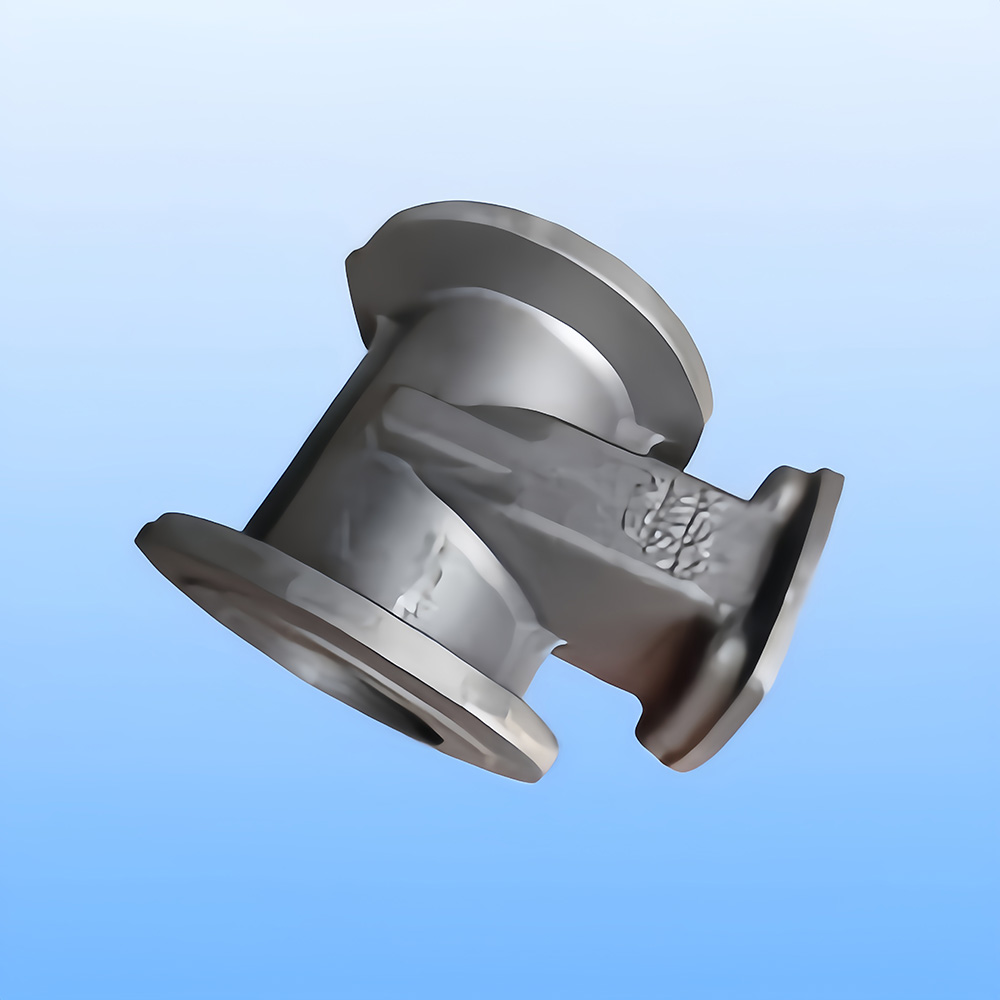

· The intense heat radiation from the molten metal during pouring causes the upper part of the mold to expand and arch, potentially leading to sand inclusions and sand holes on large flat surfaces. By positioning large flat surfaces facing down or using a tilted pouring method, these casting defects can be avoided.

3. Thin Walls Facing Down, Sideways, or Tilted:

· To prevent defects such as cold shuts and incomplete pouring in thin-walled sections, larger thin-walled areas should be placed at the bottom of the casting, or positioned on the side or tilted.

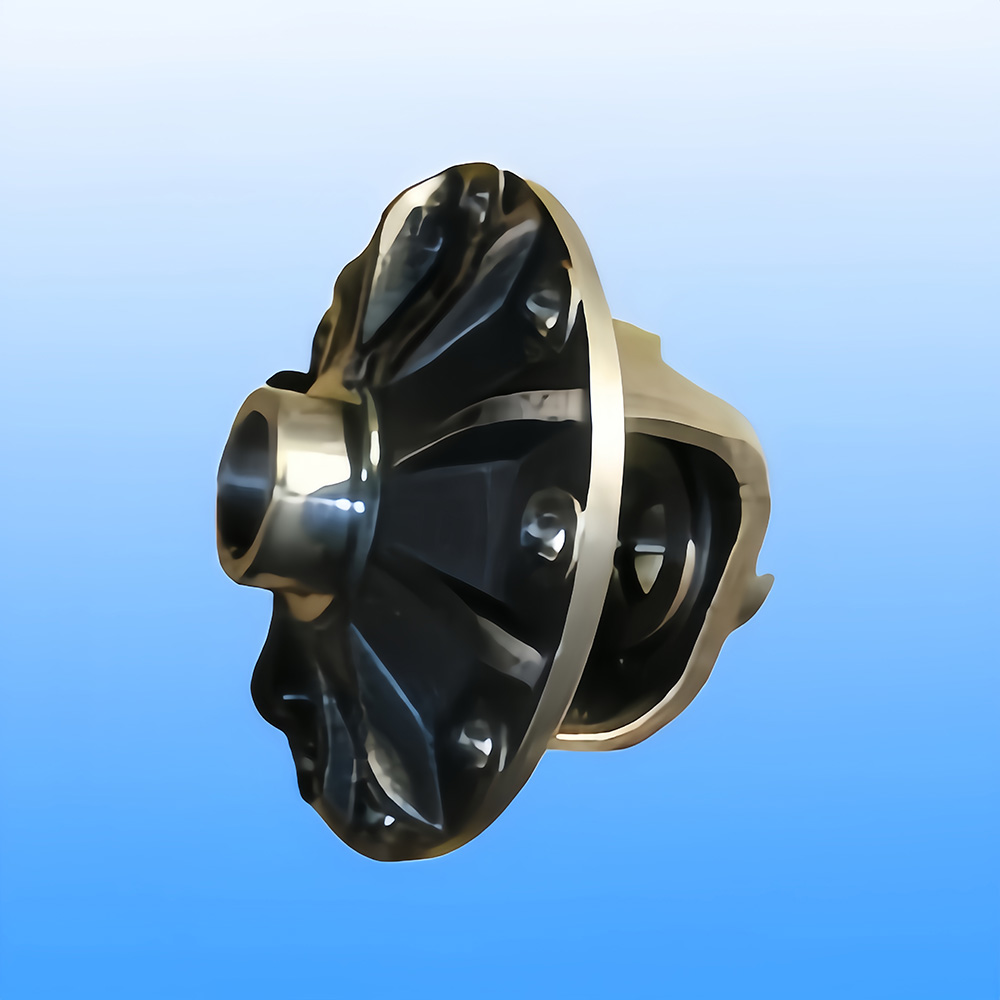

4. Thick Sections Positioned at the Top or on the Side of the Parting Line:

· The main purpose here is to facilitate the placement of risers for feeding and compensating shrinkage in thick sections.

Precision Casting Production

During the casting process, the position of the casting within the mold affects the quality, dimensional accuracy, and formability of stainless steel precision castings. The principles for selecting the casting position are:

1. Important or Main Machined Surfaces Facing Down or to the Side:

· During pouring, gases, slag, and sand particles in the mold will float upwards, potentially causing defects such as porosity, slag inclusions, and sand holes in the upper part of the casting. The lower part is less likely to have such defects, resulting in a denser structure.

2. Large Flat Surfaces Facing Down or Tilted:

· Due to the intense heat radiation from the molten metal on the upper part of the mold during pouring, the sand mold at the top may expand and arch, causing defects like sand inclusions and sand holes on large flat surfaces. Positioning large flat surfaces facing down or using a tilted pouring method can prevent these large-scale casting defects.

3. Thin Walls Facing Down, Sideways, or Tilted:

· To prevent cold shuts and incomplete filling of thin-walled sections, larger thin-walled areas should be positioned at the bottom of the casting or placed on the side or tilted.

4. Thick Sections Positioned at the Top or on the Side of the Parting Line:

· The main purpose is to facilitate the placement of risers to feed and compensate for shrinkage in thick sections.